- Ductile Iron -

- Steel Plate -

- Steel Coil -

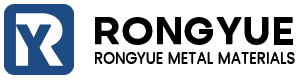

- Steel Pipe -

- Steel Rod -

- Steel Profiles -

- Steel Rebar -

- Wire Rod -

- Aluminum -

- Copper -

PRODUCT

A36/Q235/S235JR Carbon Steel Coil

- ABOUT US -

Rongyue Metal Materials

Liaocheng Rongyue Metal Materials Co., Ltd. is located in Jiajiajing Village, Fanshi County, Xinzhou City. It was established in 2002. It is a full-industry chain equipment manufacturing production base integrating mine dressing, smelting, casting and sales.

Annual production capacity of cast pipes 300,000 tons

Annual production capacity of castings 130,000 tons

Can be customized according to customer needs

Founded in 2002

Covering an area of 350 acres

With 550 employees

FACTORY

The casting production equipment consists of American Inducta medium frequency electric furnace, French technology fully automatic water cooling, hot film high-efficiency centrifuge, fully automatic core making machine, 60M continuous energy-saving annealing furnace, desktop energy-saving annealing furnace, German Cook robot, fully automatic finishing and coating line, intelligent program-controlled crane, etc. The entire production line is streamlined and intelligent.

News

In addition to the impact of the epidemic that caused the price of ductile iron pipes to fall, what other factors can affect the price of ductile iron pipes?

We know that good materials are the key to the quality of ductile iron pipes.Only by using high-quality materials can the role of ductile iron pipes be fully played. At the same time, the price of ductile iron pipes will also rise. The price of ductile iron pipes will be divided into medium, high and low grades, which corresponds to the distinction of material quality grades.

Is there any difference between the production process of ductile iron pipe and ordinary iron pipe?

Ductile iron pipes have the characteristics of simple and easy-to-obtain raw materials, low price, easy atomization of coatings, uniform composition, not easy to precipitate, not easy to clog pipes and nozzles, etc., which can reduce production costs and ensure good spraying performance.

09-16

2022

Special functions of T-type joint centrifugal ductile iron pipe

Another special function of T-type joint centrifugal ductile iron pipes is their resistance to corrosion. Unlike some other types of pipes, ductile iron pipes are not prone to rusting or corroding over time. This makes them a reliable choice for use in underground applications where they may be exposed to moisture and other corrosive elements. T-type joint centrifugal ductile iron pipes are also resistant to chemicals, making them suitable for use in industrial pipelines where they may come into contact with corrosive substances.

09-16

2022

Introduction of self-tapping screw anchor

Direct self-tapping screw-in - the self-tapping extrusion screw-in anchor rod has a drill bit on the anchor rod, and the drill rig is used to directly drive the anchor rod into the soil. The anchor rod squeezes the soil around the rod body during the screw-in process, so that the soil parameters close to the rod body are strengthened.

03-24

2023

Industrial Application of I-Beam

I-Beams, also known as H-beams or W-beams, are widely used in industrial applications due to their strength, durability, and versatility. They are typically made of steel and have a distinctive shape that resembles the letter "I" when viewed from the side.

03-06

2023

How are stainless steel pipes classified?

Stainless steel pipes are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes, as well as bimetallic composite pipes, coated and coated pipes to save precious metals and meet special requirements. There are various types and uses of stainless steel pipes, with varying technical requirements and production methods. The current production of steel pipes has an outer diameter range of 0.1-450mm and a wall thickness range of 0.01-250mm. To distinguish its characteristics, steel pipes are usually classified according to the following method.