Stainless Steel Angle Steel

- Commodity name: Stainless Steel Angle Steel

Keyword:

Stainless Steel Angle Steel

- PRODUCT DESCRIPTION

-

Product Description

Stainless steel angle steel can be composed of different force components according to the different needs of the structure, and can also be used as a connector between components. Widely used in various building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transportation machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves. Stainless steel angle steel is a carbon structural steel for construction. It is a simple section steel, mainly used for metal components and plant frames. In use, it requires good weldability, plastic deformation performance and certain mechanical strength. The raw material billet for the production of stainless steel angle steel is low-carbon square billet, and the finished stainless steel angle steel is delivered in hot-rolled forming, normalizing or hot-rolled state.

Product Parameters

Material

A36,St37,S235J0,S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540

Scope of production

H100*100-H400*400H150*75 -H900*300

Thickness

1-30mm

Width

15-400mm

Length

6m, 9m, 12mor according to customer requirements

Technology

Hot rolled, welded

Standard

ASTM,AISI,JIS,GB, DIN,EN

Surface

Galvanized, painted;or according to your requirements

supply capacity

2000tons/Day

Business Type

Manufacturer

Certificate

ISO, SGS,BV

Application

Widely used in building structures and engineering construction, such as room beams, ship beams, industrial furnaces, etc.

loading port

Any port in China

Packaging

Standard export packing or as your request

Payment Method

Wire transfer, spot letter of credit, Western Union, payment documents, acceptance documents, PayPal.

|

model

|

|

Single Angle Steel |

|

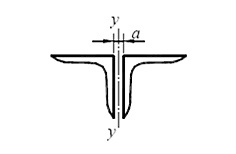

Double Angle Steel |

|||||||||||||

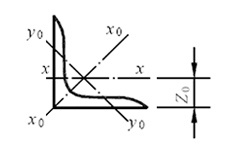

| Round Corners | Centroid Moment | Cross-sectional area | quality | Moment of inertia | Section modulus | Radius of gyration |

iy, 当 a 为下列数值 |

||||||||||

|

R |

Z0 |

A |

Ix |

Wxmax |

Wxmin |

ix |

ix0 |

iy0 |

6mm |

8mm |

10mm |

12mm |

14mm |

||||

|

(mm) |

(cm2) |

(kg/m) |

(cm4) |

(cm3) |

(cm) |

(cm) |

|||||||||||

|

L90×

|

6 |

10 |

24.4 |

10.64 |

8.35 |

82.77 |

33.99 |

12.61 |

2.79 |

3.51 |

1.8 |

3.91 |

3.98 |

4.05 |

4.12 |

4.2 |

|

|

7 |

24.8 |

12.3 |

9.66 |

94.83 |

38.28 |

14.54 |

2.78 |

3.5 |

1.78 |

3.93 |

4 |

4.07 |

4.14 |

4.22 |

|||

|

8 |

25.2 |

13.94 |

10.95 |

106.5 |

42.3 |

16.42 |

2.76 |

3.48 |

1.78 |

3.95 |

4.02 |

4.09 |

4.17 |

4.24 |

|||

|

10 |

25.9 |

17.17 |

13.48 |

128.6 |

49.57 |

20.07 |

2.74 |

3.45 |

1.76 |

3.98 |

4.06 |

4.13 |

4.21 |

4.28 |

|||

|

12 |

26.7 |

20.31 |

15.94 |

149.2 |

55.93 |

23.57 |

2.71 |

3.41 |

1.75 |

4.02 |

4.09 |

4.17 |

4.25 |

4.32 |

|||

|

L100× |

6 |

12 |

26.7 |

11.93 |

9.37 |

115 |

43.04 |

15.68 |

3.1 |

3.91 |

2 |

4.3 |

4.37 |

4.44 |

4.51 |

4.58 |

|

|

7 |

27.1 |

13.8 |

10.83 |

131 |

48.57 |

18.1 |

3.09 |

3.89 |

1.99 |

4.32 |

4.39 |

4.46 |

4.53 |

4.61 |

|||

|

8 |

27.6 |

15.64 |

12.28 |

148.2 |

53.78 |

20.47 |

3.08 |

3.88 |

1.98 |

4.34 |

4.41 |

4.48 |

4.55 |

4.63 |

|||

|

10 |

28.4 |

19.26 |

15.12 |

179.5 |

63.29 |

25.06 |

3.05 |

3.84 |

1.96 |

4.38 |

4.45 |

4.52 |

4.6 |

4.67 |

|||

|

12 |

29.1 |

22.8 |

17.9 |

208.9 |

71.72 |

29.47 |

3.03 |

3.81 |

1.95 |

4.41 |

4.49 |

4.56 |

4.64 |

4.71 |

|||

|

14 |

29.9 |

26.26 |

20.61 |

236.5 |

79.19 |

33.73 |

3 |

3.77 |

1.94 |

4.45 |

4.53 |

4.6 |

4.68 |

4.75 |

|||

|

16 |

30.6 |

29.63 |

23.26 |

262.5 |

85.81 |

37.82 |

2.98 |

3.74 |

1.93 |

4.49 |

4.56 |

4.64 |

4.72 |

4.8 |

|||

|

L110× |

7 |

12 |

29.6 |

15.2 |

11.93 |

177.2 |

59.78 |

22.05 |

3.41 |

4.3 |

2.2 |

4.72 |

4.79 |

4.86 |

4.94 |

5.01 |

|

|

8 |

30.1 |

17.24 |

13.53 |

199.5 |

66.36 |

24.95 |

3.4 |

4.28 |

2.19 |

4.74 |

4.81 |

4.88 |

4.96 |

5.03 |

|||

|

10 |

30.9 |

21.26 |

16.69 |

242.2 |

78.48 |

30.6 |

3.38 |

4.25 |

2.17 |

4.78 |

4.85 |

4.92 |

5 |

5.07 |

|||

|

12 |

31.6 |

25.2 |

19.78 |

282.6 |

89.34 |

36.05 |

3.35 |

4.22 |

2.15 |

4.82 |

4.89 |

4.96 |

5.04 |

5.11 |

|||

|

14 |

32.4 |

29.06 |

22.81 |

320.7 |

99.07 |

41.31 |

3.32 |

4.18 |

2.14 |

4.85 |

4.93 |

5 |

5.08 |

5.15 |

|||

|

L125× |

8 |

14 |

33.7 |

19.75 |

15.5 |

297 |

88.2 |

32.52 |

3.88 |

4.88 |

2.5 |

5.34 |

5.41 |

5.48 |

5.55 |

5.62 |

|

|

10 |

34.5 |

24.37 |

19.13 |

361.7 |

104.8 |

39.97 |

3.85 |

4.85 |

2.48 |

5.38 |

5.45 |

5.52 |

5.59 |

5.66 |

|||

|

12 |

35.3 |

28.91 |

22.7 |

423.2 |

119.9 |

47.17 |

3.83 |

4.82 |

2.46 |

5.41 |

5.48 |

5.56 |

5.63 |

5.7 |

|||

|

14 |

36.1 |

33.37 |

26.19 |

481.7 |

133.6 |

54.16 |

3.8 |

4.78 |

2.45 |

5.45 |

5.52 |

5.59 |

5.67 |

5.74 |

|||

|

L140×

|

10 |

14 |

38.2 |

27.37 |

21.49 |

514.7 |

134.6 |

50.58 |

4.34 |

5.46 |

2.78 |

5.98 |

6.05 |

6.12 |

6.2 |

6.27 |

|

|

12 |

39 |

32.51 |

25.52 |

603.7 |

154.6 |

59.8 |

4.31 |

5.43 |

2.77 |

6.02 |

6.09 |

6.16 |

6.23 |

6.31 |

|||

|

14 |

39.8 |

37.57 |

29.49 |

688.8 |

173 |

68.75 |

4.28 |

5.4 |

2.75 |

6.06 |

6.13 |

6.2 |

6.27 |

6.34 |

|||

|

16 |

40.6 |

42.54 |

33.39 |

770.2 |

189.9 |

77.46 |

4.26 |

5.36 |

2.74 |

6.09 |

6.16 |

6.23 |

6.31 |

6.38 |

|||

|

L160×

|

10 |

16 |

43.1 |

31.5 |

24.73 |

779.5 |

180.8 |

66.7 |

4.97 |

6.27 |

3.2 |

6.78 |

6.85 |

6.92 |

6.99 |

7.06 |

|

|

12 |

43.9 |

37.44 |

29.39 |

916.6 |

208.6 |

78.98 |

4.95 |

6.24 |

3.18 |

6.82 |

6.89 |

6.96 |

7.03 |

7.1 |

|||

|

14 |

44.7 |

43.3 |

33.99 |

1048 |

234.4 |

90.95 |

4.92 |

6.2 |

3.16 |

6.86 |

6.93 |

7 |

7.07 |

7.14 |

|||

|

16 |

45.5 |

49.07 |

38.52 |

1175 |

258.3 |

102.6 |

4.89 |

6.17 |

3.14 |

6.89 |

6.96 |

7.03 |

7.1 |

7.18 |

|||

|

|

12 |

16 |

48.9 |

42.24 |

33.16 |

1321 |

270 |

100.8 |

5.59 |

7.05 |

3.58 |

7.63 |

7.7 |

7.77 |

7.84 |

7.91 |

|

|

14 |

49.7 |

48.9 |

38.38 |

1514 |

304.6 |

116.3 |

5.57 |

7.02 |

3.57 |

7.67 |

7.74 |

7.81 |

7.88 |

7.95 |

|||

|

16 |

50.5 |

55.47 |

43.54 |

1701 |

336.9 |

131.4 |

5.54 |

6.98 |

3.55 |

7.7 |

7.77 |

7.84 |

7.91 |

7.98 |

|||

|

18 |

51.3 |

61.95 |

48.63 |

1881 |

367.1 |

146.1 |

5.51 |

6.94 |

3.53 |

7.73 |

7.8 |

7.87 |

7.95 |

8.02 |

|||

|

L200× |

14 |

18 |

54.6 |

54.64 |

42.89 |

2104 |

385.1 |

144.7 |

6.2 |

7.82 |

3.98 |

8.47 |

8.54 |

8.61 |

8.67 |

8.75 |

|

|

16 |

55.4 |

62.01 |

48.68 |

2366 |

427 |

163.7 |

6.18 |

7.79 |

3.96 |

8.5 |

8.57 |

8.64 |

8.71 |

8.78 |

|||

|

18 |

56.2 |

69.3 |

54.4 |

2621 |

466.5 |

182.2 |

6.15 |

7.75 |

3.94 |

8.53 |

8.6 |

8.67 |

8.75 |

8.82 |

|||

|

20 |

56.9 |

76.5 |

60.06 |

2867 |

503.6 |

200.4 |

6.12 |

7.72 |

3.93 |

8.57 |

8.64 |

8.71 |

8.78 |

8.85 |

|||

|

24 |

58.4 |

90.66 |

71.17 |

3338 |

571.5 |

235.8 |

6.07 |

7.64 |

3.9 |

8.63 |

8.71 |

8.78 |

8.85 |

8.92 |

|||

Packing and delivery

It has modern factories and advanced production equipment. The process equipment is automated, intelligent, digital and information-based. It has its own laboratories, testing rooms and independent R&D departments.

Qualifications and Honors

Factory appearance

It is a specialized manufacturer and seller of carbon steel, steel bars, stainless steel, galvanized, hot-rolled seamless steel pipes, precision seamless steel pipes, cold drawn seamless steel pipes, alloy pipes, special-shaped pipes, etc.

Application areas

Its products are suitable for various fields such as automobiles, motorcycles, power, machinery, hydraulic accessories, bearings, pneumatic components, oil cylinders, coal mines, conveyors, boiler equipment, pipelines, engineering, etc. Our company has 5 perforation units, 30 precision rolling machines, and 6 cold drawing machines.

Get A Quote

Note: Please leave your email address, our professionals will contact you as soon as possible!

Related Products